Liquid Eductors for Handling Dry Solids

267 SOLIDS/LIQUID MIXING EDUCTORS

- For In-Line Mixing and Transfer

- Of Granular Solids and Liquid

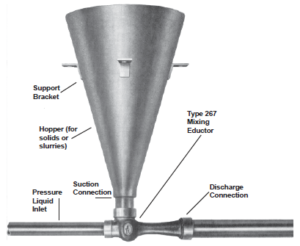

The Type 267 Solids/Liquid Mixing Eductor is a hopper-equipped jet ejector designed to entrain and mix granular solids or slurries with liquid and discharge the mixture to a receptacle or transfer it to a desired location. Originally developed to mix drilling mud for oil industry applications, these devices have proved to be so effective and versatile that they are being applied to increasing numbers in diverse industries including the food, chemical processing, pharmaceutical, glass, power, and others.

The unit consists of a body, nozzle, and hopper. All threaded components of the same size are interchangeable regardless of the material (nonmetallic bodies and nozzles are cemented together). Four support brackets are provided as shown. As shown in Table 2, a variety of materials are available. In addition to those noted, any workable material can be supplied on special order.

In operation, liquid under pressure issues through a converging nozzle in the eductor and produces a high velocity jet. This creates a suction in the body of the eductor and causes the suction material to be drawn into the eductor and entrained by liquid.

Both the motive liquid and the entrained material are intimately mixed in the throat of the eductor and are discharged against back pressure. Table 3 shows the estimated capacities and water consumptions for Solids/Liquid Mixing Eductors.

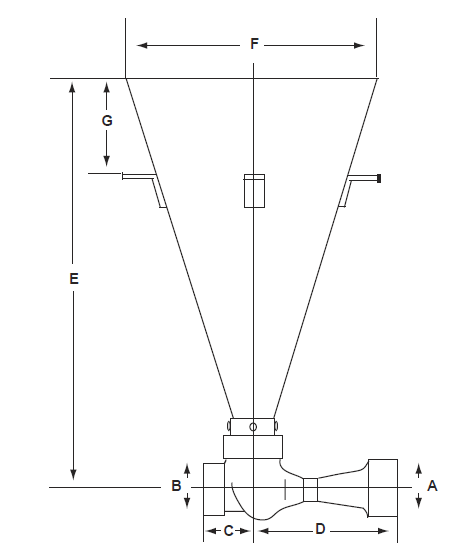

TABLE 1 SHOWS SIZES AND DIMENSIONS FOR FIG 267 SOLIDS/LIQUIDS MIXING EDUCTORS

| SIZE | A | B | C | D | E | F | G | WEIGHT |

| 1 | 1 | 3/4 | 1-1/2 | 4-3/16 | 42 | 24 | 9 | 32 |

| 1-1/2 | 1-1/2 | 1 | 2 | 6-1/2 | 41-1/2 | 24 | 9 | 34 |

| 2 | 2 | 1-1/4 | 2-1/4 | 7-5/8 | 41 | 24 | 9 | 36 |

| 2-1/2 | 2-1/2 | 1-1/2 | 2-11/16 | 9-1/4 | 41-1/4 | 24 | 9 | 42 |

| 3 | 3 | 2 | 3-1/8 | 11-1/4 | 40-3/4 | 24 | 9 | 50 |

- Dimensions are in inches.

TABLE 2 SHOWS AVAILABLE MATERIALS

| SIZE | CAST IRON | BRONZE | 316SST | KYNAR | PVC | NOZZLE ONLY MONEL |

| 1 | x | x | x | x | x | |

| 1-1/2 | x | x | x | x | x | |

| 2 | x | x | x | x | x | |

| 2-1/2 | x | x | x | |||

| 3 | x | x | x | x |

Note: Hoppers with threaded connections are supplied in these materials in all sizes – Steel, *316SS, PVC.

*316SS stocked in 1″, 1-1/2″ and 2″ sizes.

TABLE 3 SHOWS ESTIMATED ENTRAINMENT CAPACITIES FOR 1″ SIZE FIG 267 EDUCTOR

| MOTIVE PRESSURE (PSIG) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 |

| ENTRAINMENT, CU.FT. / HR OF GRANULAR SOLIDS | 2.5 | 7.0 | 14 | 17 | 19 | 21 | 22 | 23 |

| MOTIVE FLOW (GPM) | 6.1 | 7.0 | 7.9 | 8.6 | 9.2 | 9.9 | 10.5 | 11.1 |

TABLE 4 SHOWS RELATIVE CAPACITIES

| SIZE | 1 | 1-1/2 | 2 | 2-1/2 | 3 |

| CAPACITY RATIO | 1.0 | 2.89 | 4.0 | 6.25 | 9.0 |